Starting in SOLIDWORKS 2019, users will be able to extend this automation to turned components for lathes using SOLIDWORKS CAM Professional. Tolerance-Based Machining in SOLIDWORKS 2018 started with understanding tolerances on milled components. Tolerance-Based Machining Tolerance-Based Machining in SOLIDWORKS CAM 2019 introduces some powerful new capabilities that dramatically reduce the time required to generate CNC programs for Turned parts with close tolerances, and surface finish requirements. This extended functionality will allow companies to standardize their manufacturing process more accurately.

In SOLIDWORKS 2019, users will be able to assign feature geometry and material to a specific machine. SOLIDWORKS CAM 2018 allowed users to capture rules based on feature geometry and material type. It is common to find facilities that have Lasers, Plasma, Mills, and Lathes to meet the growing demand to be a “one-stop shop” for their customers. Machine-Specific Rules (machining strategies)ĭue to the affordability of CNC equipment today, most shops are adding equipment that covers multiple disciplines. These two additions will allow HSM toolpaths to be used in more machining strategies to reduce cycle times and improve machine output. In SOLIDWORKS 2019 users will be able to leverage two new options in Volumill: Rest Machining and Zig Zag toolpaths for constant cutting on long parts.

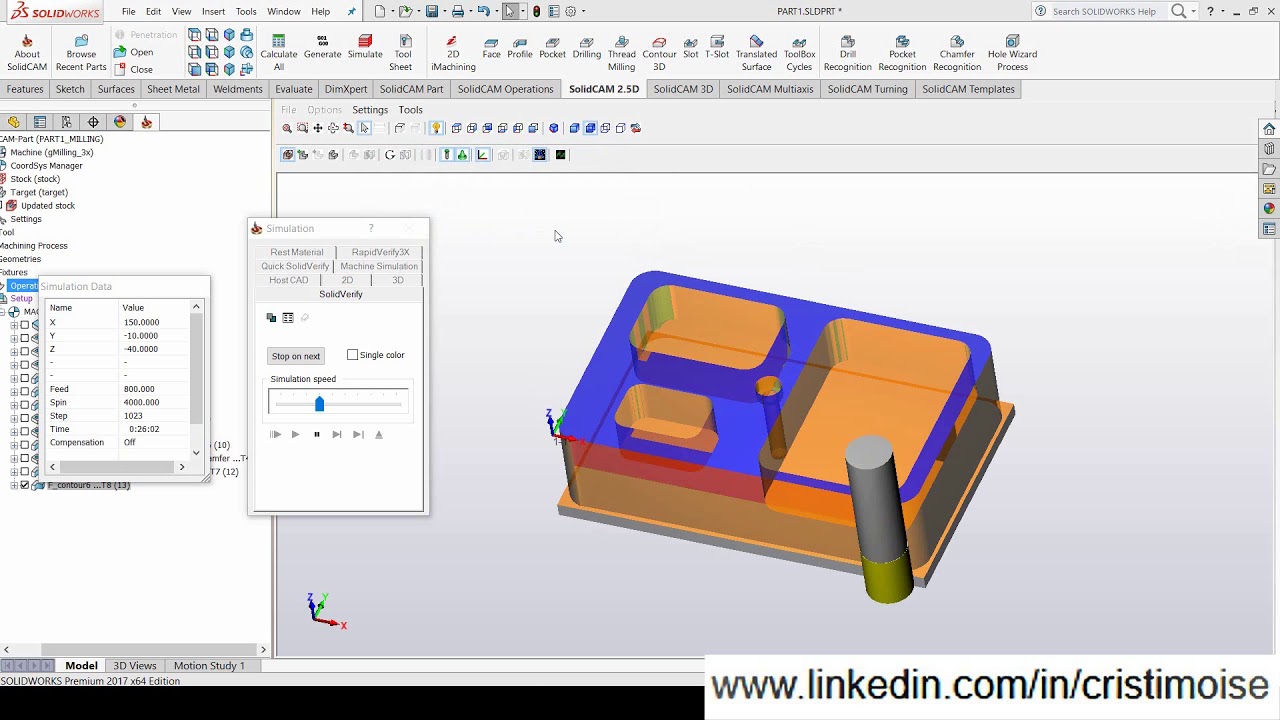

In 2018 SOLIDWORKS CAM Professional provided Volumill toolpath to improve tool life and shorten cycle times on milled components. Let’s take a quick look at some of the key features of SOLIDWORKS CAM in 2019.Īs manufacturing becomes more competitive around the world, it is important to get the most out of all aspects of the manufacturing process. Throughout this first year we have spent a lot of time with customers seeing all the cool things they manufacture and gained some important feedback for future versions! It has been a full year since we released SOLIDWORKS CAM Powered by CAMWorks. It is hard to believe we are already looking at another release of SOLIDWORKS.

0 kommentar(er)

0 kommentar(er)